Heating and cooling systems are made up of pipes and the connectors and transitions that bring them together. There is a whole class of parts, mainly boots, elbows, and wyes. The round duct fittings are needed so that the air moves throughout the system seamlessly and without interruption. The choice of fittings is just as important as the pipes themselves.

Galvanized, flexible steel duct connectors are some of the most common and best solutions when attempting to bring a heating and cooling system to completion. The connectors and associated clamps are meant to accommodate specific duct measurements. For example, if the system is comprised of 4-inch diameter pipes, then that calls for connectors or round duct fittings that are the same size, though some room can be left for expansion and contraction – hence the term ‘flexible’.

The best duct connectors possess certain characteristics that make them an ideal product for ductwork. Lightweight material construction gives way to durability and reliability. Clamps used around the fittings help create a tight seal which saves money on energy.

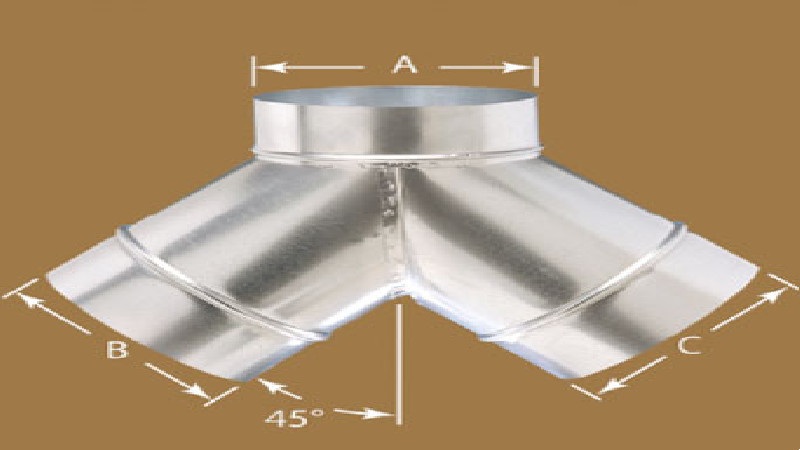

Each fitting or connector serves a certain purpose. Duct boots act as a transition point from round pipes to a grille or a register. Steel round elbows connect pipes through where a turn is necessary. A duct reducer fitting does just what the name implies; it reduces the size of a pipe so that it can run through a specific area that is more enclosed than in other spaces. Starting collars are a go-between for round pipes and flat surfaces.